9 Considerations Before you Outsource your Custom Test Equipment Development

Selecting the right supplier for your custom automated test system

You likely either work in a manufacturing plant or an R&D lab and have a role in test. Your role might focus on product validation, or maybe you’re on the manufacturing test side of things. Either way, you need some custom test equipment developed and you’re thinking of outsourcing. But how do you know what questions to ask?

Here are 9 important questions to help prepare you for supplier selection.

How do you get a warm fuzzy that they can solve your problem?

In the realm of things that don’t exist yet (your solution), it can be a challenge to discern whether or not the custom test equipment supplier can solve your problem. Most of it boils down to past experience with enough similarities to your problem to set your mind at ease. This experience is generally illustrated in 3 ways: case studies, metrics, and focus areas.

- Case studies – while it’s unlikely you’ll find a case study that matches your needs exactly, you want to find examples that illustrate the supplier has delivered similar solutions (if interested, you can see our case studies here).

- Metrics – this will generally be an indicator of how many solutions of a particular category a supplier has delivered (you can see some of our metrics sprinkled here).

- Focus areas – These tend to be clusters of application areas or industries that the supplier has experience with ( see Problems We Solve, Test Equipment for Aerospace / Defense, Electromechanical Test Equipment, Test Systems for Electrical Components and Systems,

Automotive Test Equipment, Custom Test Systems for Medical Device Industry).

For example, maybe you want a supplier:

- with a lot of particular LabVIEW experience,

- or maybe it’s important to you for them to have experience with NI’s PXI platform,

- or maybe it’s important to you that they do work in your industry.

- or maybe if you develop electronically-focused products, that’s important,

- or if you develop electro-mechanical products, it’s important that they have experience testing those.

Some suppliers may focus on things like battery test, or RF test, or semiconductor test, or bed of nails testing. Not us. We tend to focus a fair amount of our efforts on testing “things that move”. Specifically, test systems for complex or mission-critical electromechanical products.

What are they not good at?

There are a couple aspects to consider for this one. You want to know what they’re not good at from 2 perspectives: (1) a “type of problem they solve” standpoint, and (2) a “way they do business” standpoint.

For example, from a “type of problem they solve” standpoint, we’re not good at:

- In-circuit prober testing

- Heavy-duty RF consumer product testing

- Test equipment where the main needs are met with a PLC (we’re an NI and LabVIEW house)

From a “way they do business” standpoint, we’re not good at:

- Winging it – we like some structure

- Creating solutions for companies that do pure R&D – more nebulous flexibility than we like

- Long-term on-site staffing for months at a time – but our engineers are effective as remote staff augmentation

- Solutions that need very rapid response 24×7 support – we’d contract to another support company

- Delivering complex systems to China and SE Asia – support and trade complexities

How deep is their bench?

You’re buying a capability, since the end product (your custom test equipment) doesn’t exist yet. Your needs revolving around flexibility, responsiveness, risk reduction, and price sensitivity will drive your desires for depth. Bench depth can affect:

- your current solution needs,

- support of that solution,

- and development of future custom test equipment.

Questions to ask:

- If the primary engineer developing my solution quits or retires, is there someone that can fill in?

- What’s your typical response time if something is broken and needs to be fixed?

- How do I know if you have the financial ability to build my system before you get paid?

- How long have you been around and do you have any plans to close shop in the foreseeable?

How much does geography matter to me?

This one is pretty straightforward. How important is it to be able to have someone on-site within a few hours? Or, will phone, email, and remoting in generally be sufficient with the occasional plane ride for the supplier?

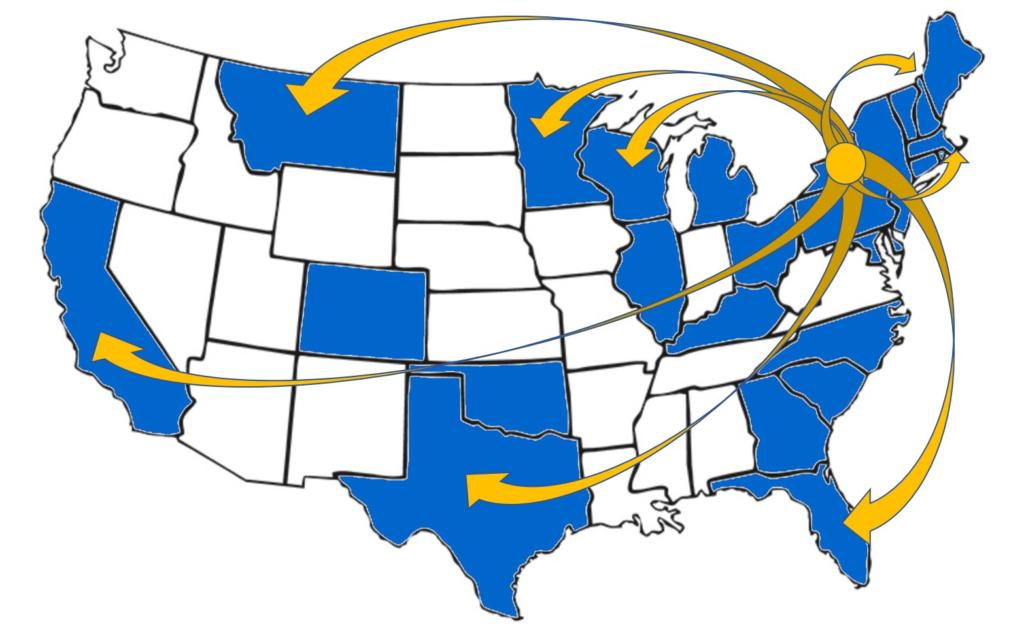

We have a mix of customers, some right in our back yard, and others in various parts of the US:

What are they like to work with?

This is a personalities/culture question. You might not think you’ll care, but relationships matter a lot when developing anything custom. While you’re not on the development team, you are working together to make sure you get the test system you want/need in the end.

You’ll likely get an initial impression about the company from their website, but pay close attention during the sales process, especially once they bring an engineer into the discussion. In our case, that’s more than likely the person you’ll be working with during the development of your test equipment. Think about these things:

- Do you feel like you’ll get along with them okay?

- Do they seem generally realistic (not overly optimistic or pessimistic)?

- Do they keep their commitments (even small ones)?

- Do you feel like they’re being real with you, or are they putting on an act to win your business?

- If you poke at them a bit, can they handle it, or does it seem like they’ll crack easily?

How expensive are they?

Of course cost is a factor. It should be. It’s not the only thing, but it of course matters. Besides the obvious price in the quote, the other external costs come from things like:

- The likelihood that the company will nickel and dime for every Engineering Change Order.

- The likelihood of poor usability of the test system, that slowly erodes minutes of your internal labor over long periods of time.

- The likelihood of poor reliability of the test system.

- Additional time-saving functionality (e.g., automated test report generation or good formatting of your test data for easy analysis) could lower the cost of ownership of what initially appears to be a more expensive solution.

How quickly will they respond when I need them?

This will generally be determined by 2 main factors:

- How busy your main POC is at the point in time you reach out to them.

- How many engineers know about your system, in case the main POC is unavailable.

Ask the supplier questions around these factors as they relate to your needs.

How long will it take to get my new custom test equipment?

This depends on 3 main factors:

- How big of an effort it is to develop your solution.

- How many engineers are going to work on your solution.

- How busy those engineers are with other customers.

Again, ask questions. To start to bound the problem for you, the following scenarios are a good starting point generally speaking (verify, because the variance is sizable, especially based on how busy the development team is with other customers):

- Lower end test system, where the hardware is readily available COTS, and the software development is pretty basic – ~2 months.

- Middle of the road test system, where there’s some custom hardware or mechanical integration, and the software is middle of the road – ~5 months.

- Higher end turnkey test system, with a custom signal conditioning board, lots of channels, custom enclosure, lots of complicated test software to develop – ~10 months.

How long will it take to get an update to my custom test equipment if I need an update months or years after it’s been delivered?

This can be divided into two categories:

- A quick tweak – this is something small like maybe your operators would prefer a slightly larger button to push to accept a part, or maybe an equation needs to be scaled differently. This category is defined by taking a couple hours of engineering effort. It’s not unheard of for this sort of update to occur within 24 hours if it’s time-critical. Otherwise this sort of update can usually be made within a few business days. Of course, if the system needs to be re-validated, such as for a FDA-regulated medical device tester, then more time will be needed.

- A significant functional update – this is something that would generally be several days to a few weeks of effort. This might include a new test step, adding in data logging or report generation capabilities, or supporting a new measurement device. This category would generally fall into the ~2 months sort of timeframe, but you’ll need to confirm for your situation of course.

Next Steps

Feeling like you want to chat about your custom test equipment needs? Want to see if we meet your criteria for a custom test equipment supplier? Reach out to start the conversation.

Deep into learning mode? Check out these resources:

- How to Diagnose Failing Custom Test Equipment – process, causes, getting started

- Test Automation Best Practices

- 5 Keys to Upgrading Obsolete Manufacturing Test Systems

- What is LabVIEW? – A developer’s perspective

- Custom Automated Test System Buyers Guide

- Product Testing Methods – for industrial hardware products

- Hardware Product Testing Strategy – for complex or mission-critical parts & systems

- Commissioning Custom Test Equipment– process, pre-commissioning checklist, and gotchas

- Hardware Test Automation Tools – for complex electromechanical product manufacturing

- How to prepare for when your test team starts to retire

- Practical manufacturing test and assembly improvements with I4.0 digitalization

- What to do with your manufacturing test data after you collect it

- How Aerospace and Defense Manufacturers Can Make the Assembly and Test Process a Competitive Advantage

- 9 Considerations Before you Outsource your Custom Test Equipment Development

- Reduce Manufacturing Costs Report

- Improving Manufacturing Test Stations – Test Systems as Lean Manufacturing Enablers To Reduce Errors & Waste