Online Monitoring of Industrial Equipment using NI CompactRIO

Improving Maintenance of expensive industrial equipment

Client – Large Industrial Equipment Manufacturer

Challenge

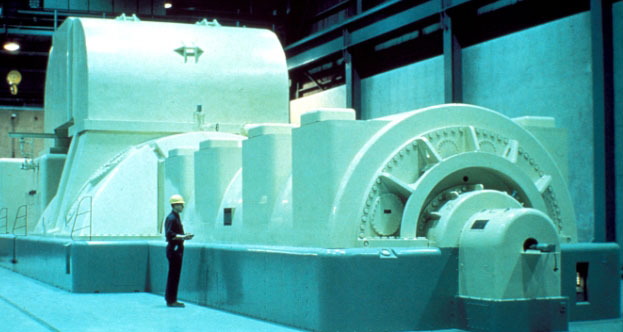

The maintenance of the equipment was not always done at the prescribed intervals because the cost of shutting down the plant is significant. This sometimes resulted in an equipment failure. This particular application is for equipment/machinery in the energy/power industry (a generator).

Solution

The online monitoring system monitors a particular parameter of interest to send warnings and alarms to the control room so that the operators know when maintenance needs to be performed on the particular part of interest. This system has been installed in multiple plants.

Benefits

- Enables condition-influenced maintenance intervals vs periodic intervals

- Reduces probability of catastrophic failure by providing warning indicator

System Overview

The system monitors the generator collector health. NI-based data acquisition hardware acquires the signal of interest, logs the raw data, processes the parameter of interest, and triggers/sends warnings and alarms to the control room. LabVIEW FPGA was used for analog and digital IO and a sensor check. LabVIEW Real Time was used for the calculation, data logging, serving data to the HMI and alarm/warning checking.

| SOFTWARE FUNCTIONS |

|---|

| Touchscreen GUI for data/alarm display and system configuration |

| Data logging |

| Signal processing and alarming |

| HARDWARE USED (selected by customer) |

|---|

| NI cRIO |

| NI Touch Panel Computer |

| Multiple NI C Series Modules |

| INTERFACES / PROTOCOLS |

|---|

| TCP/IP |

*- images are representative, not actual