Use Of Embedded Systems in Industrial Automation

Use Cases & Case Studies

Use cases for embedded systems in industrial automation can be divided into two main classes: machine control and machine monitoring.

To make sure we’re on the same page, we’re NOT talking about test system automation. If you’re interested in that topic, please see here.

Use cases for embedded systems in industrial automation can be divided into two main classes: machine control and machine monitoring.

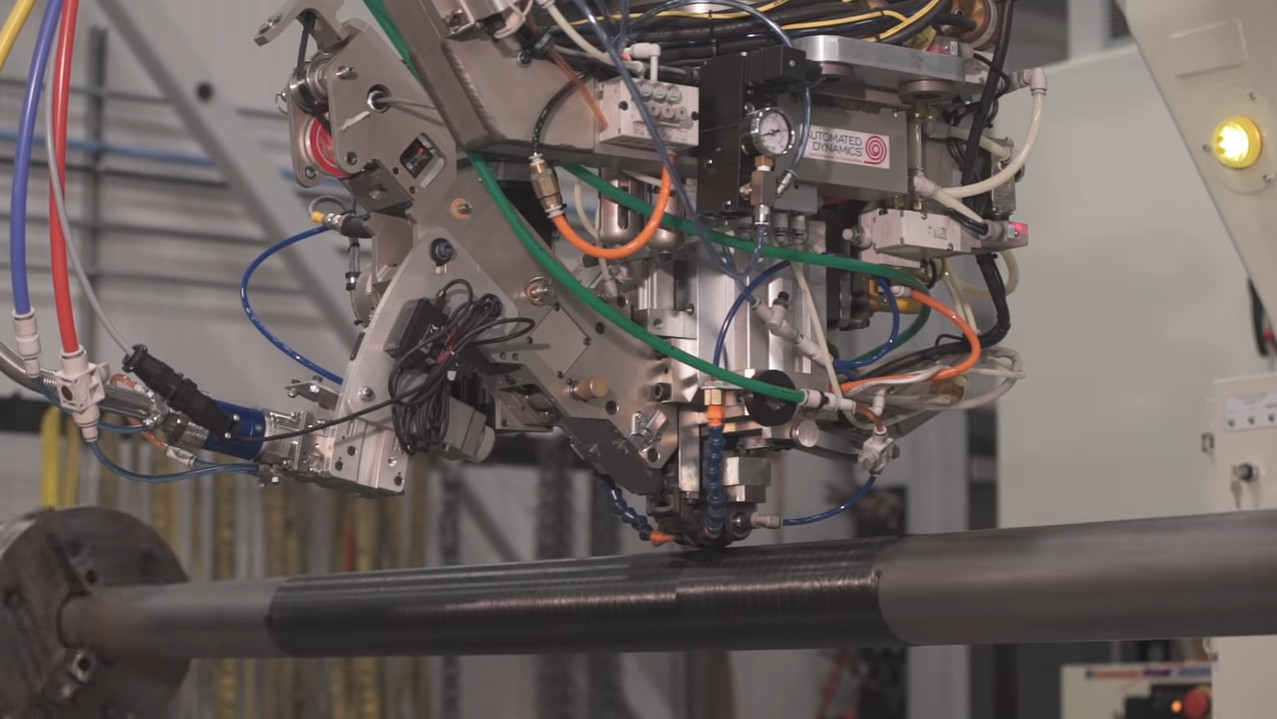

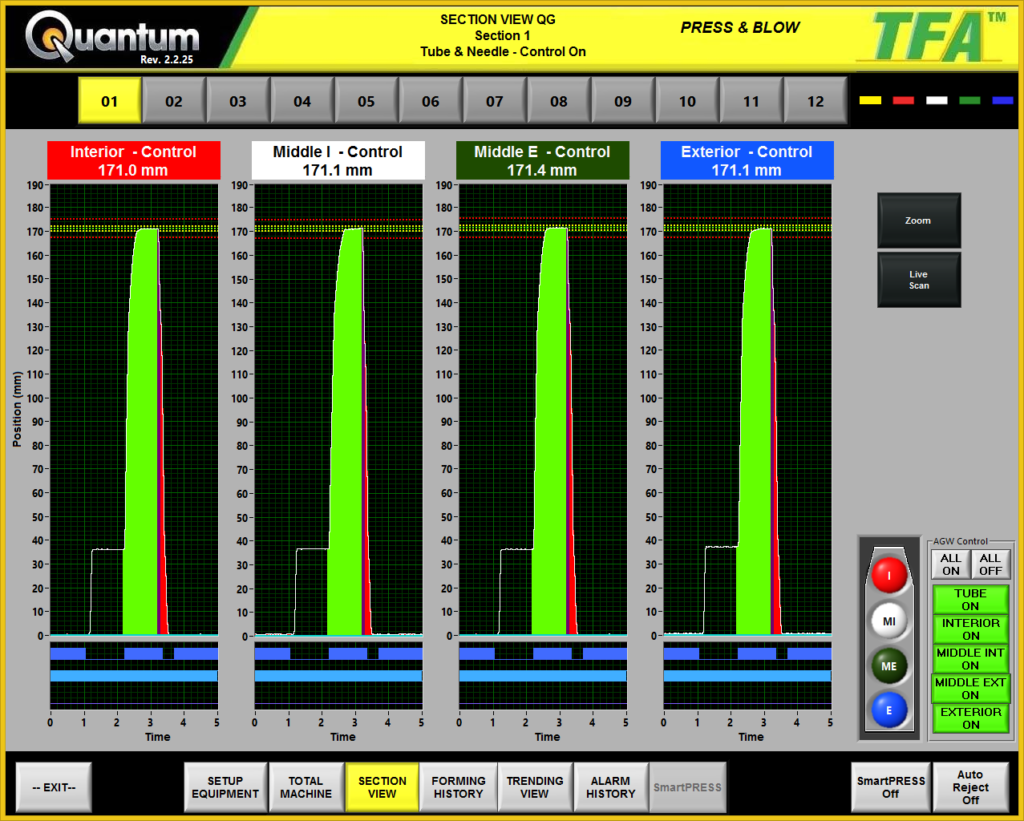

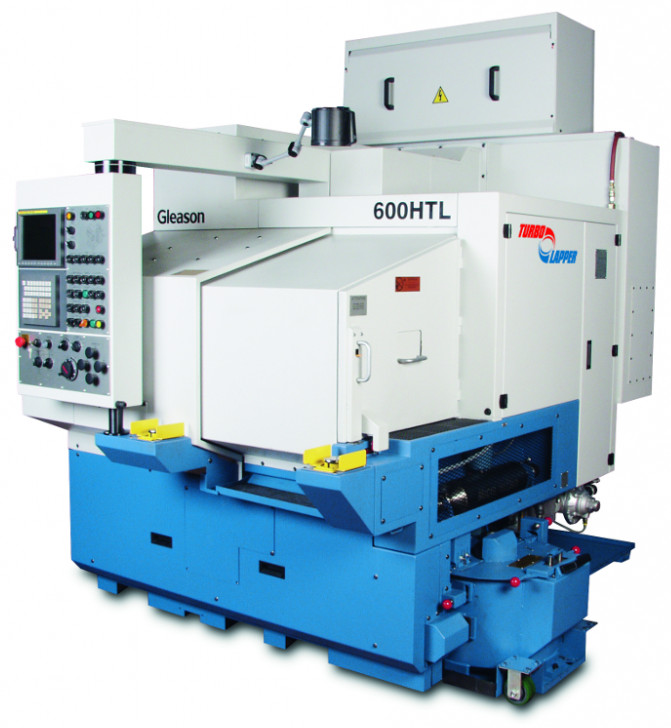

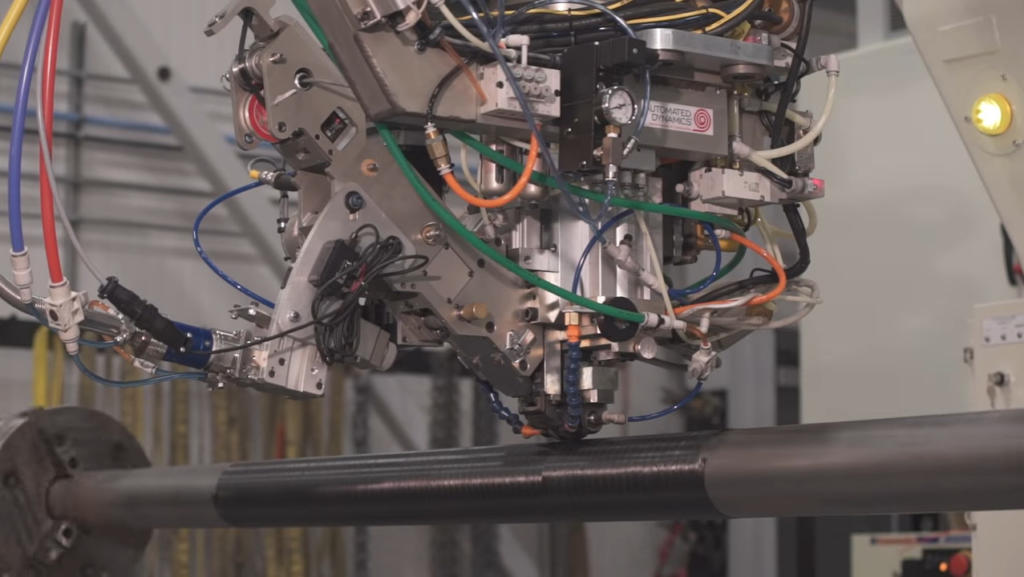

Embedded machine/equipment control – for this use case, the embedded system is controlling some aspect of the industrial machine/equipment. It might be controlling the tight tolerance timing of a particular manufacturing process, it might dynamically adapt production of the part to improve product quality, or it might control the operation of a piece of industrial equipment out in the field. Some examples of machine control applications include:

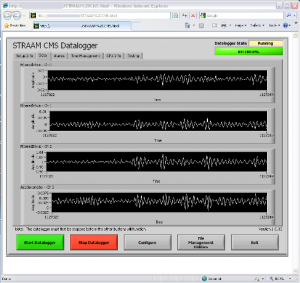

Machine/equipment monitoring – this could include generalized monitoring of a machine or it could be more focused specifically on condition monitoring, which generally has the objective of improving machine up-time/reliability and/or reducing maintenance costs and production loses. Some examples of machine/equipment monitoring applications include:

If you’re looking for help with using embedded systems for your industrial application, there are two things you’ll want to do to get started: (1) develop a good set of requirements (see here for an industrial embedded requirements template) and (2) find a vendor capable of helping you (check out this Outsourcing Industrial Embedded System Development Guide). If you want to chat about your application with us, you can reach out here.