Industrial Equipment Remote Online Condition Monitoring

Using NI CompactRIO

Client

A manufacturer of large industrial mission-critical equipment in the electrical energy / power industry.

Challenge

Our client had three main goals in mind. They wanted to:

- Decrease unanticipated downtime and maintenance expenses

- Provide a more complete picture of machine operation and state

- Improve equipment usage tracking.

Solution

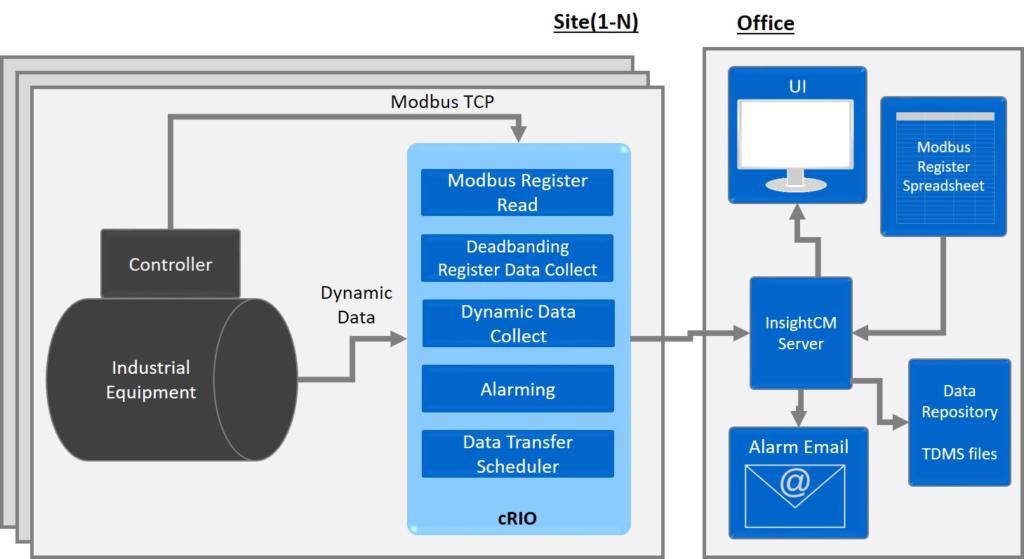

The solution is a multi-node (i.e. multi-site) remote monitoring system that utilizes an NI cRIO-based controller with customized NI InsightCM monitoring software.

Benefits

- Monitors vibration signals to predict expensive equipment failures

- Monitors current machine state via Modbus from other equipment in the system, including the primary system controller

- Provides alerts via email when any designated parameter is out of range

System Overview

The remote monitoring system monitors equipment condition by taking several vibration signal measurements along with reading over 500 Modbus registers. Local InsightCM vibration analysis on the cRIO extracts key features from the accelerometer data. Limit detection is run on these features and other equipment state and alarms are triggered when data is out of bounds. Information collected at multiple sites is sent to a central location either at periodic intervals or based on an alarm condition.

| SOFTWARE |

|---|

| NI InsightCM software |

| Modbus register configuration & reading |

| Dead banding-style register data collection to decrease amount of data captured and transferred |

| Dynamic signal data capture |

| Alarming detection |

| Data transfer scheduling |

| Semi-real-time alarm channel display |

| HARDWARE USED |

|---|

| NI cRIO |

| NI IEPE Analog Input Module |

| Microsoft Windows Server to host the NI InsightCM server software |

| INTERFACES / PROTOCOLS |

|---|

| Modbus TCP |

| Ethernet TCP/IP |