Pump Test Station Used Across Multiple Locations Worldwide

Client – ITT Goulds Pumps

Challenge

Pumps are used for everything from sump pumps for the consumer home market all the way to large pumps for industry capable of moving thousands of gallons per minute. Just as varied is the fluid being pumped: from water to slurries to hydrocarbon-based fluids.

Pump manufacturers typically build and test in plants across the world and each of those facilities is responsible for testing every pump manufactured at that site to ensure that the pump will perform as the customer expects. These tests are well defined and based on standards such as API, ANSI and other organizations. These standards provide test procedures but do not give details as to how to perform the tests. Each site typically tests their product without guidance as to how to satisfy the aforementioned standards. As a result, differing hardware and software solutions are usually put in place to test the individual site’s products.

Such varied testing systems make it exceedingly difficult to compare test results across testing sites, both within plants and between plants.

We were asked by our client to create a homogeneous test platform with which they could compare data across manufacturing plants and test sites within the plants as well as automate calculations of plant performance metrics and reporting.

This client engaged us to develop and implement a software and information storage solution that could run the prescribed tests on any testing site and make these data available to their engineers. These tests were to be semi-automated and guide the test operator through a test ensuring that the procedure and the resulting data were collected in the same manner on every test site, worldwide.

Solution

The Pump Test Globalization application consists of the following sub-applications:

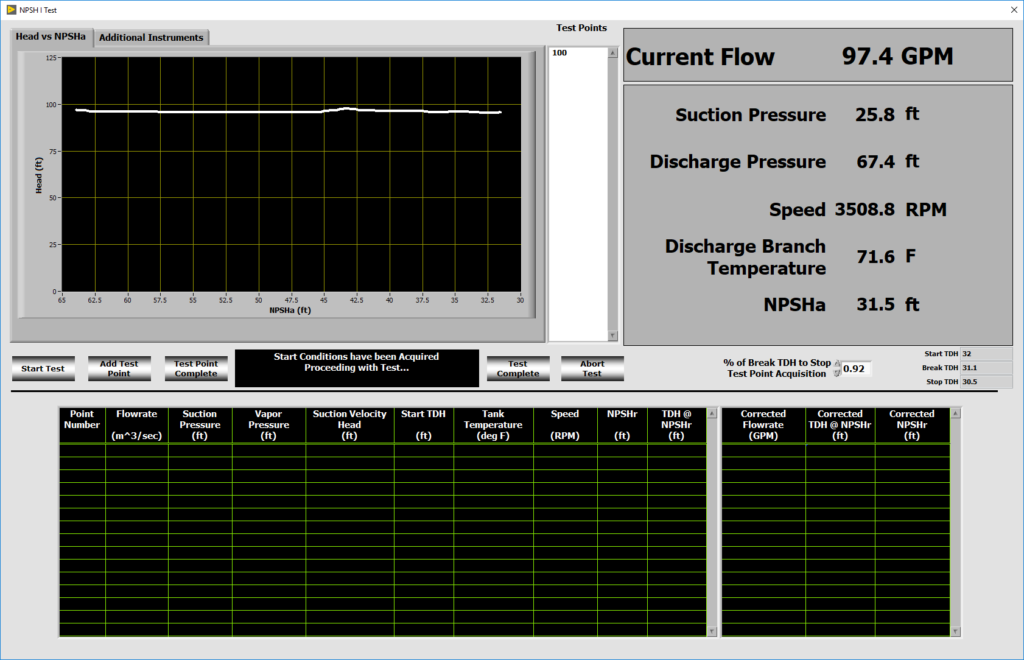

- A Pump Test application that can run 1 of five different tests simultaneously to reduce the amount of time the UUT is under test. A separate data file is generated for each test and those data files are stored in the database along with the test results.

- A Test Configuration application that helps to manage the orders and the tests association with those orders.

- A Report Generation application that creates a report for each test run on a pump. Additional performance graphs are generated along with options for graphs depicting vibration and orbital performance of the pump.

Benefits

- Standardization of testing technique – now each pump will be tested with the same procedures and calculations/algorithms used are standardized across all manufacturing test sites.

- Standardization of report content and presentation – now every customer that purchases a pump from our client, regardless of origin of manufacture, will receive a report with identical information presented and that information will have been derived from the same calculations/algorithms.

- Ability to generate manufacturing performance data – metrics such as first pass yield may be calculated for all manufacturing sites. Data from all manufacturing sites may now be compared.

- Abstraction of data acquisition hardware – measurement data can be acquired from a variety of sources including OPC servers and NI DAQ Hardware. With this abstraction, the client’s existing hardware was reused where it made sense and replaced with new hardware as needed.

System Overview

We developed Pump Test, Pump Test Configurator and Pump Test Report Generator applications to allow our client’s engineers and operators to:

- Run one or a series of guided tests that visually provides pump performance feedback during the test.

- Configure a test for a specific pump model number and serial number. This configuration is read in by the Pump Test software to set up the test according to the configuration.

- Generate a report that would be sent with the pump to their customer showing how the pump performed and that it met the customer’s requirements.

The pump test software was developed in LabVIEW and interfaced with a SQL database to acquire the configuration information necessary to set up and run the required tests. The resulting data acquired during the test, both raw data acquired from the sensors and calculated data used to characterize the pump being tested, are saved to the database. Both high speed (10 kS/s) and low speed (10 S/s) data are acquired simultaneously and stored into one data file for archival storage and retrieval if additional analysis is required. The high-speed data are for vibration and orbital measurements and low speed data are for pressure, temperature, rpm and flowrate type measurements.

The pump test configuration software was also developed in LabVIEW and is a separate application that uses a SQL database on the back end. The database is located on a secure server and has been designed to retain the following information:

- Lists of all the manufacturing and test facilities.

- List for all the motors used for running the pumps.

- List for all the available sensors and hardware for each test station for every manufacturing plant.

- Ability to associate each sensor with a hardware channel for acquisition.

- Create and edit orders that contain pump specific information such as model number and serial number.

- Create and edit test configuration information for a given order.

The report generation software was also developed in LabVIEW and provides the user a means to create standard reports for each of the test types. Additional addendums to the standard report can be created to include graphs utilizing the high-speed data such as vibration and orbital information.

| SOFTWARE FUNCTIONS |

|---|

| Data Acquisition |

| Test Sequencing |

| Test Configuration Verification |

| Language Localization |

| Metric or SAE Units |

| Multi-Level User Authentication |

| 5 Standardized Test Types |

| Generate Standard Table-Based Reports |

| Generate Pump Performance Graphs |

| Generate Vibration and Orbital Graphs |

| Pump Order Management Tools |

| Sensor Management Tools |

| Test Configuration Management Tools |

| HARDWARE USED |

|---|

| NI cDAQ Signal Conditioning Chassis |

| Variety of NI cSeries Signal Conditioning Modules |

| Various OPC Servers for PLC Communications |

| Pressure Sensors |

| Flowmeters |

| Vibration Sensors |

| Displacement Sensors |

| Temperature Sensors |

| Torque Sensors |

| Speed Sensors |